DTH Shanks Operation& Maintanence

Grinding of Button Bits

When the button bit was first introduced, it was widely assumed that sharpening was unnecessary. Such an understanding was not unfortunate since the button bit is also subjected to wear and tear even if it may give, when compared to the conventional bits; a 300% increase in footage before sharpening becomes necessary. If re-sharpening is imperfect or if not done at the correct intervals, the button bit is likely to lose penetration speed and thereafter be subject to failure. While it was granted that in softer formations, an unsharpened button bit may continue to serve without carbide failure long after it ought to have been withdrawn from service it must also be appreciated that a similarly abused bit in a massive crystalline formation will very quickly fail. It is essential to remember that in hard rock, button bits are susceptible to failure from over drilling in the same way as any other bit.it is more economical to regrind too soon than to run the risk of damage by regrinding too late.

Equipment Required

- A reliable pencil type air grinder capable of approximately 25000rpm.

- Spindle mounted grind stones, 1” (or 1.5”) x 1” (or 0.75”) x0.25” spindle, and suitable for high speeds.

- One unused new bit similar to the one being grounded (this may be dispensed by experience), or a button guage.

- Safety glasses and protective clothing.

Pencil type air grinders consume very little air, and it is best if bit regrinding is done while drilling is in progress. Ringing a button bit does not require brute strength; rather it is an art and the lighter the touch, the better. With proper care the button bit will greatly reduce drilling costs

When to Regrind

If a new bit is likely to fail due to material or manufacturing defects, it will normally do so in the initial half regrind life. The nature of such defects is dealt with later, but it is wise to withdraw and check any new bit early in life. Sometimes the gauge buttons may show slightly uneven wear or removal, i.e. while most show normal wear patterns the odd button may show excessive wear. This may be attributed to the slightly variation in setting of the gauge buttons. In such a vase, one or two buttons may be over ground while majority still requires no grinding. Prolonged initial drilling may thus lead to individual inset failure.

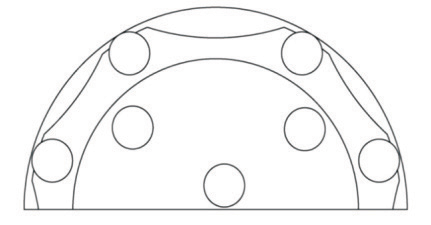

Guage Buttons

When the bit is withdrawn from the bore, it will be noticed that the gauge buttons are worn in such a way that the outermost wear faces are equidistant from the bit center. When regrinding the gauge buttons it is essential to maintain the equidistance. This is best achieved by grinding in such a way as to leave a very tiny unground portion on the extreme outer edge of each button. A perfect circle of the buttons can thus be maintained

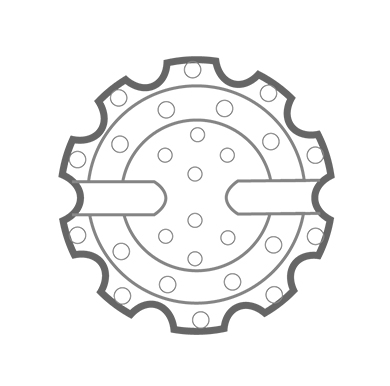

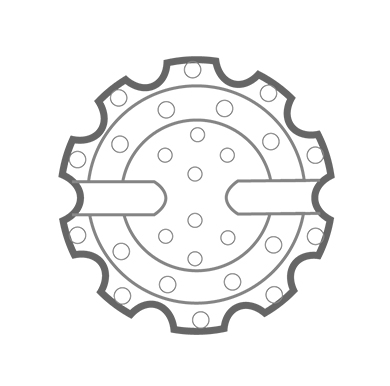

Button Grinding

The object of grinding is to return the carbides to their original shape. This, in effect, means the removing of an equal depth of carbide from unworn areas of each insert. For the gauge buttons this means that most of the material must be ground from the inner side of the button hemisphere gradually extending around until only the slight unground outer portion is left as mentioned earlier. For the inner buttons the grinding must be done around the base of the hemisphere where it emerges

Steel Grinding

It will be noticed that after the button grinding is complete, there may remain an excess of steel between the buttons. This must be removed. More significantly, the chip-ways around the periphery of the bit must be restored to approxi- mately to the original depth to facilitate free scavenging of cuttings from the bit face.in bits with central flushing, special attention must be paid to see that the free flow of exhaust air from the hammer is not in any way impeded by metal expansion around the flushing hole. Such an obstruction can seriously affect the efficiency of the hammer, and must be removed while grinding.

Anti Taper

Only the slightest anti-taper is required at the periphery of a well-designed button bit. It is essential to remember that the gauge buttons are inserted at an angle to the face buttons. As a consequence, if the anti -taper is excessive, the gauge button may fallout during work. It is rarely necessary to grind much from the periphery as the natural wear of the steel in work automatically reduces the bit body diameter.

Finishing

During the above mentioned operation, it is wise (until experience makes it necessary) to check the reground bit carefully against a new unused bit of same type, or by using a suitable gauge. This helps in seeing that the contours and gradients confirm as nearly as possible to the original.

Check List

- See that the face buttons are so ground that they are equal in height and in same horizontal plane.

- See that the gauge buttons, with respect to their outer periphery, are in the same radius. Each button should show at its outer edge a very slightly unground portion.

- Check the buttons individually to see that they are roughly hemispherical in shape and not lob sided.

- See that all chip ways are clear and adequate both on cutting face and ground the bit circumference.

- Allow 3 degrees of anti-taper not more

- See that the hammer exhaust passage within the bit is clear.

- See that the reground bit counters confirm to the new unused bit.

General Comments

In general, a button-insert type of bit, compared to a cross or carset bit, will give two to four times the life between regrinds. It should be ground when the width of the flat developing on the outside edge of the gauge buttons is 0.25-0.33 times the diameter of the button insert itself. In soft ground this can be extended slightly but very hard rock the lesser figure should be taken as a guide. Although a well-grounded button bit will drill slightly faster than a similar cross bit, the main advantage of the button lies in its longer life between regrinds.

Why Button Bits Fail

Two types of button failures are noticed

- Button loss

- Button breakage

Failure in Type – Loss of Buttons

- MANUFACTURING DEFECT

- This normally occurs only very early in life, usually before the first regrind.

- BAD BIT GRINDING

- In this case the side supportive steel may have been removed when grinding. The hole becomes elongated and the button is lost.

- UNDERFEEDING WHILE DRILLING IS IN PROGRESS

- In such a case, there is tendency for the hammer blows to drive the carbide inserts out of the body. It is, therefore important that adequate feed pressures be given at all times.

- WEAR AND TEAR

- Frequently the first sign that bit has completed its life the “pop-out” of one or more gauge buttons, which means that they have common loose in the steel bit body. The correct use of rotation speed and feed pressures will, however, go along way towards increasing bit life.

Failure in Type - Broken Buttons

- FAULTY CARBIDE

- In button bits this is very rare.

- BAD HANDLING

- Due to bad handling in transit carbides may chip.it is well protect carbides at all times when they are not in actual use. A wooden box with compartments for bit storage is recommended.

- OVER DRILLING OR IMPROPER GRINDING – “THE LOB SIDED INSERT”

- These are the most usual causes of button breakage or buttons coming loose in the steel bit body. Normally it is the gauge buttons that are most seriously affected. Gauge buttons that break will usually be found to have sheared within the body itself. This is indicative of “pinch” action resulting from insufficient or improper grinding.

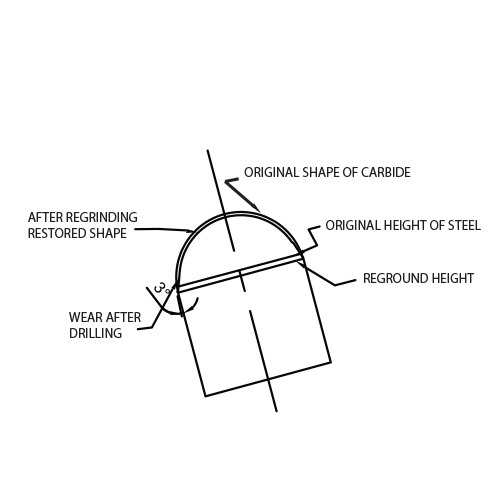

The diagram clearly indicates why this occurs. As the apex of each gauge- carbide wears, the carbides are subjected to increased side thrust. Instead of hemisphere chipping a clear hole for the bit to follow, the sides of the bit and the sides of the carbide inserts forced into undersize bore. If this is not corrected by regrinding, the stresses finally become so severe that the inserts are either sheared or forced out of the bitbody.

Bad grinding has exactly the same effect. It is essential to maintain the hemispherical shape of the new carbide. Fur- thermore, the apex of the hemisphere must be true to the axis of the insert. If this is not observed while grinding the “lob-side inset” fault will develop in such a way that the apex of the gauge button insert hemispheres will start to shift towards the center point of the rock bit. The results are same as over drilling and broken or lost inserts will normally be results.

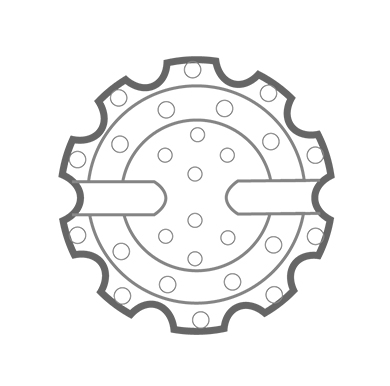

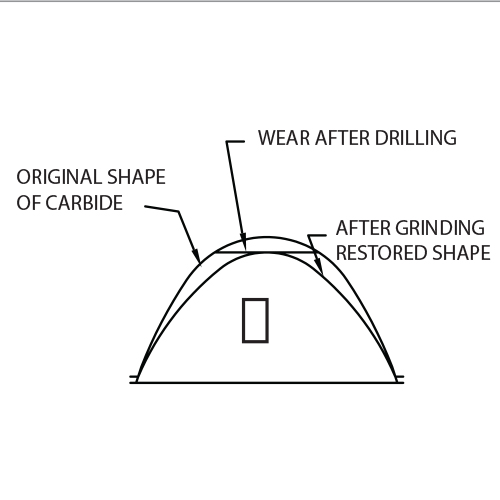

OVER DRILLING OR IMPROPER GRINDING – “THE FLAT HEMISPHERE”

The second type of insert type due to over drilling or bad is illustrated in the diagram. Here the true axis/apex relationship is retained but instead of a hemisphere the insert is allowed to develop a pronounced sub hemispherical contour. Due to the flattened nature of the insert hemisphere, the tendency is for the inserts to crush rather than chip the rock. The height of the apex of the insert above the stee bit body should be half the diameter of the insert. Check this point after grinding with a vernier gauge or an insert template. The results of following the flat hemisphere fault to develop will be put excessive shock loads on the equipment. Apart from a reduced penetration speed, this can result in insert shatter, failure of the steel bit body or hammer component failure. Proper grinding is the only answer.

Breakage of Carbide Inserts

Finally, carbide inserts will break quite spectacularly if in contact with steel or other inserts in the bore. After a failure, all carbide and steel must be removed from the bore before drilling is continued. Buttons bits have a large advantage over the conventional cross insert bit in that the failure of one button does not normally result in the breakage of other buttons and the bit may continue to be used satisfactorily even after inserts have failed. If a button breaks, grind away any projecting carbide, regrind the entire bit, and carry on. The WDS button bit is a perfect model of skilled craftsmanship. The finest materials and the most meticulous care go into making. At every stage of manufacture, the button bit is checked and rechecked to ensure the final product a maximum of durability, efficiency and profitability . WDS button bits are the products of years of painstaking research and the unending quest for perfection.