Introducing Forged Drill Rods

At Sai Deepa, January was a busy month. We recently commissioned a very large machine which takes us miles ahead in the field of superior manufacturing. It is a forging machine which is commonly called a bumping or upsetting machine. We have procured the latest and fully automatic version for our manufacturing facility at Hyderabad. It can run 24x7 with full robotic efficiency.

At Sai Deepa, January was a busy month. We recently commissioned a very large machine which takes us miles ahead in the field of superior manufacturing. It is a forging machine which is commonly called a bumping or upsetting machine. We have procured the latest and fully automatic version for our manufacturing facility at Hyderabad. It can run 24x7 with full robotic efficiency.

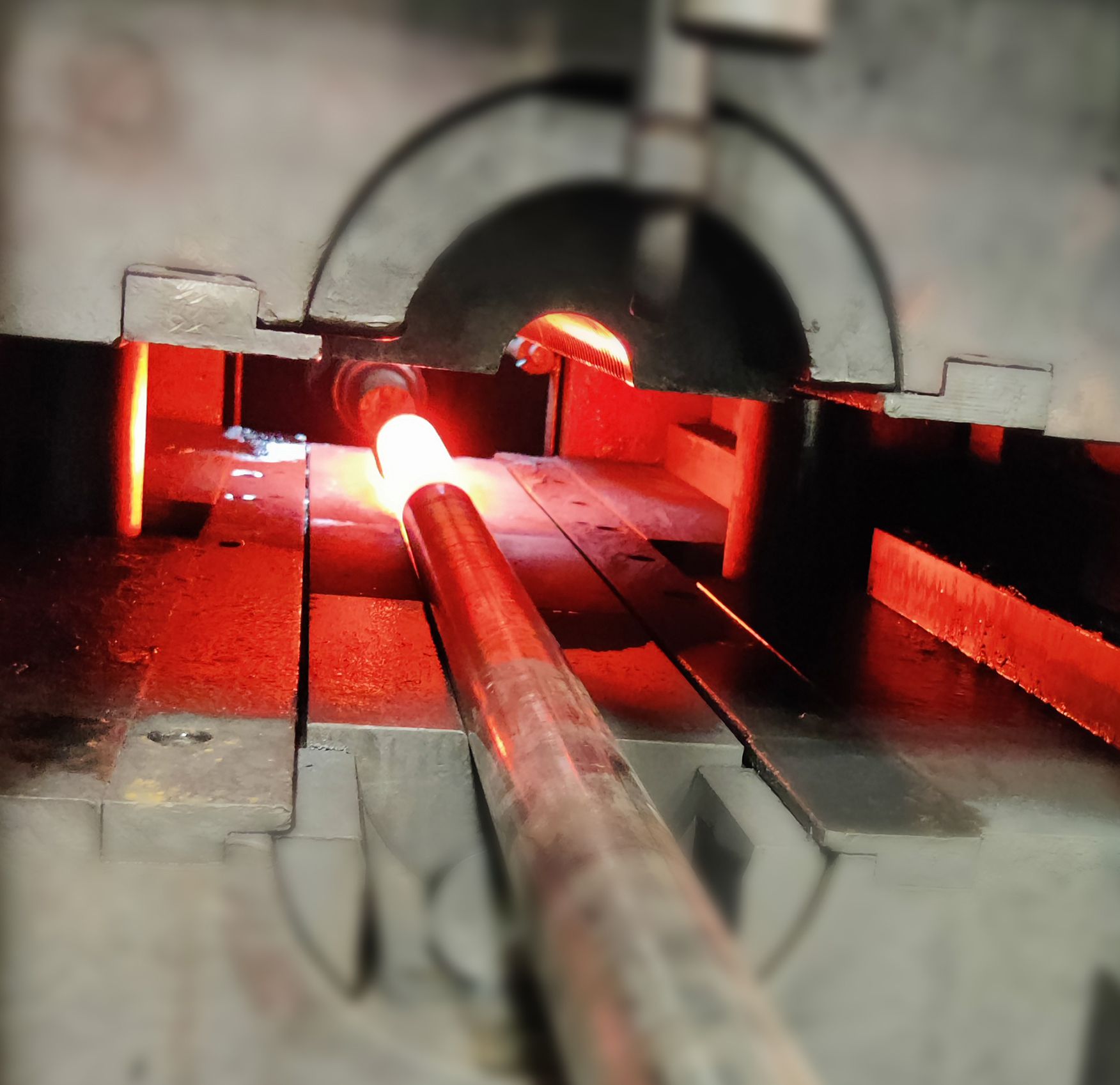

In this machine the material is fed, and the translational motion of the integrated main die assembly is used to perform cropping; then, upsetting is performed; the working method eliminates the need for a separate cropping mechanism, while at the same time, the parts in the integrated main die assembly can be replaced and adjusted from outside the machine body, thus improving upsetting efficiency.

Why Is This Machine So Important ?

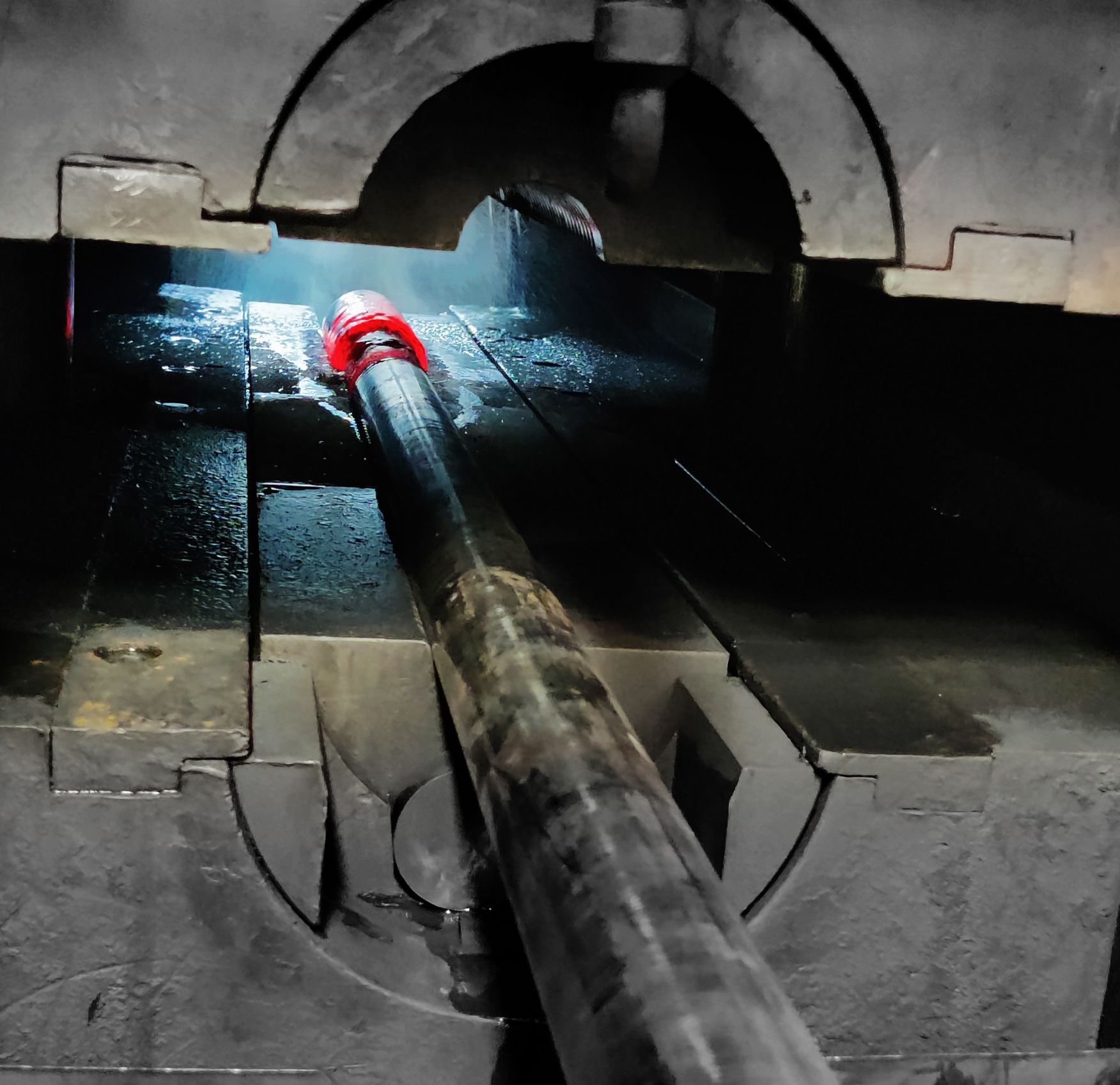

Other manufacturers friction-weld the MF rods. This creates a transmission area between the coupling and the rod. This is the reason for inconsistence in performance. It is called the ring weld, which has a thinner wall section with sharp edges. This leads to a mechanical failure. The design can also interrupt in flushing leading to more wear & slower feeds. Overall, the technique of friction welding has higher chance of failures & can increase your cost per meter.

The Upsetting machine creates a forged integrated coupling end. This is a homogeneous unified joint between the coupling and the rod. The metallurgical steel flows are far more stronger. The transition zone is smoother & gives better life.

Forged Rods

No Joints, integrated one piece.

Strong, Safe & Lasts Long.

Higher life, Lower cost per meter.

Fully Automated process 24x7 operation.

.JPG)

Frictional Welded Rods

Two welded parts.

Unsafe.

Weaker Joint.

Lower Life.