Winner Of Performance

The Laser Cladding Technology.

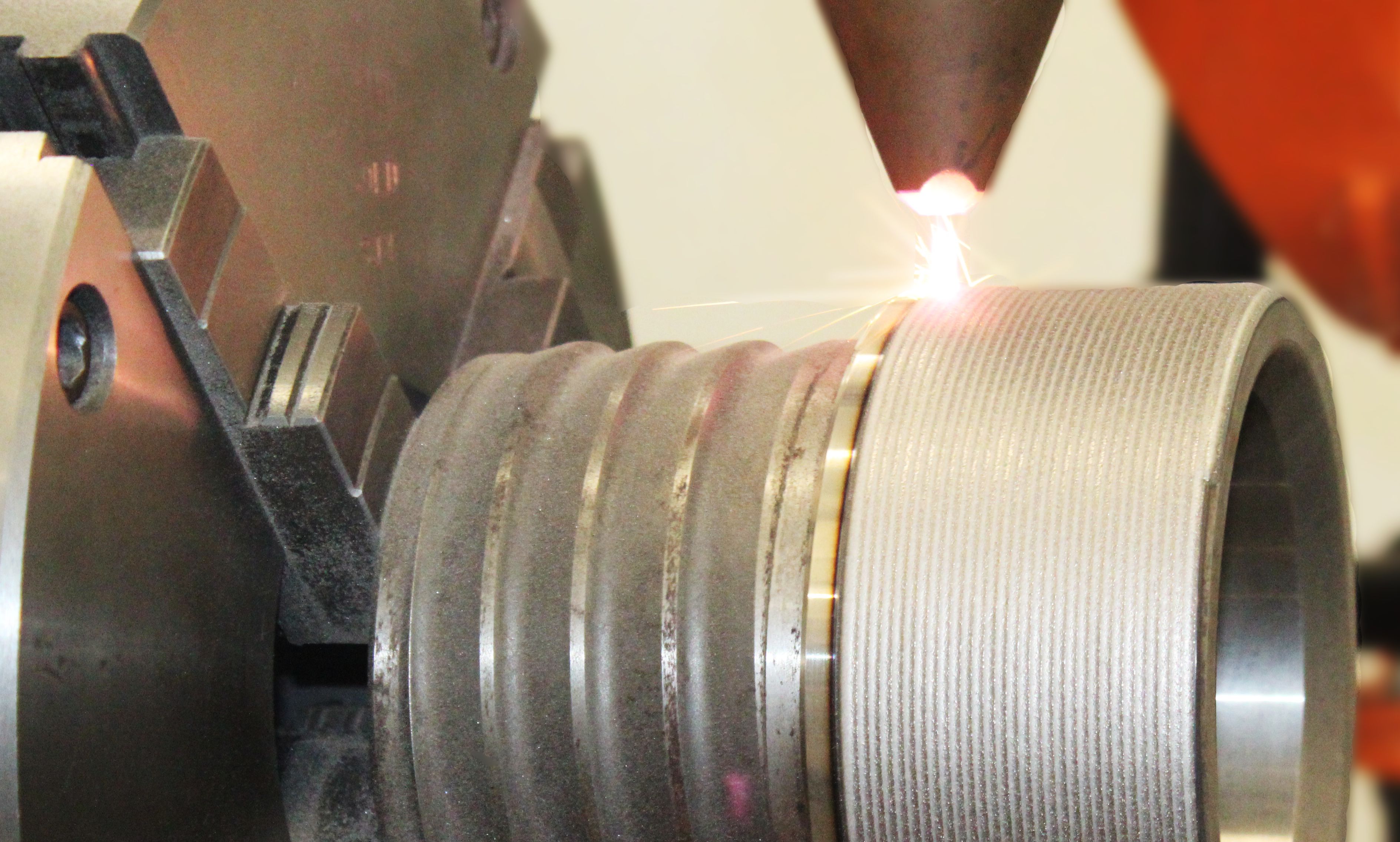

Laser cladding is a method of depositing material by which a powdered or wire feedstock material is melted and consolidated by use of a laser to coat part of a substrate or fabricate a near-net shape part (additive manufacturing technology).

It is often used to improve mechanical properties or increase corrosion resistance and fabricate metal matrix composites. Surface material is laser cladded directly onto a highly stressed component, i.e. to make a self-lubricating surface. (Wikipedia).

This process has the following advantages:

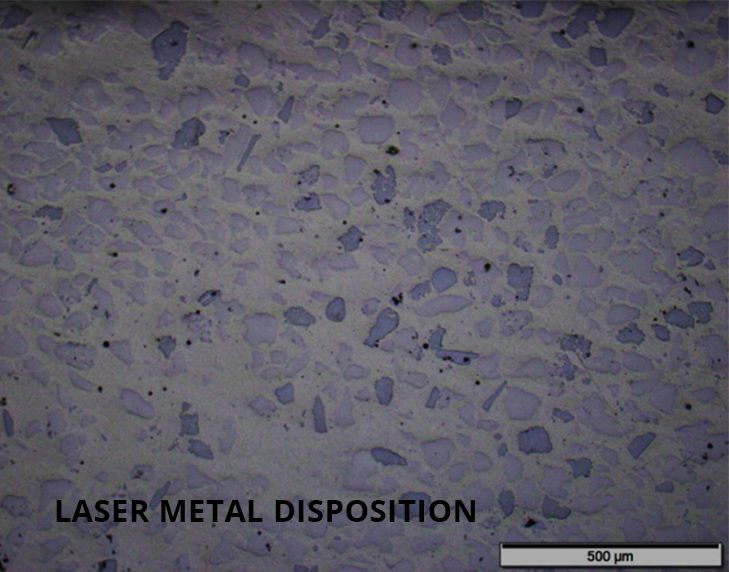

1: Higher wear resistance

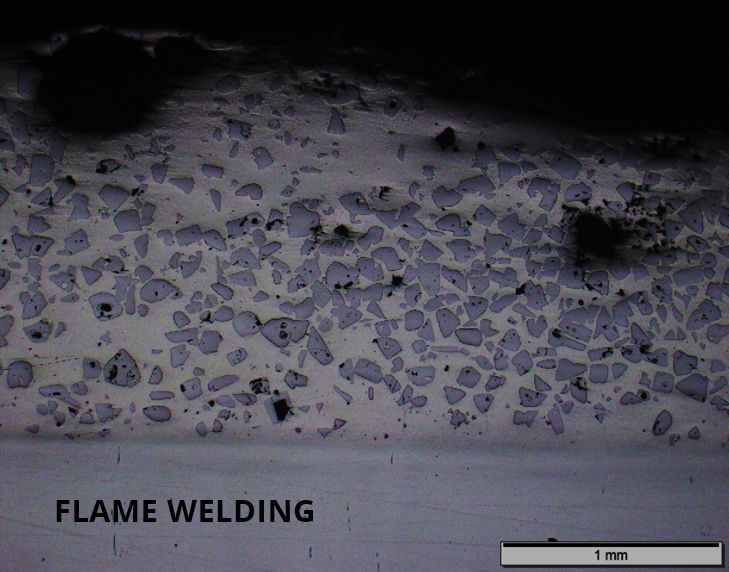

2: Uniform distribution of Tungsten Carbides

3: Localized heat input through Laser preserves microstructures of heat treated steel

4: Uniform hardness along the depth

5: Scalability and Productivity with consistent quality

How different it is from the regular process – See the following pictures taken in our Lab.

And not just the lab, but we would like to share a real-time case study. We tried our products & compared it with competition. The details are provided for your reading.

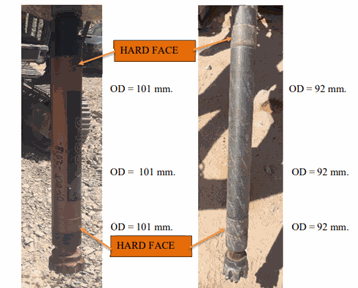

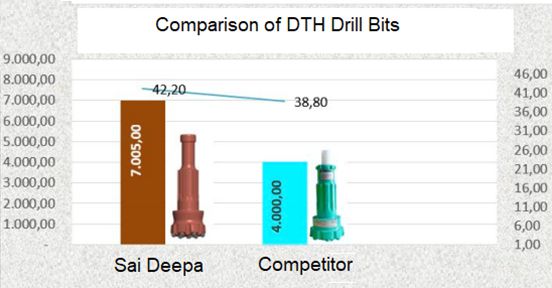

The actual site results of Sai Deepa’s Down the hole hammer JDC45S & bit S4 127 mm convex combi bit tested in medium hard limestone application proves that it is a clear winner of the segment. This hammer is reversible and with hard facing protection on the ends of the WEAR SLEEVE and Chuck. The bit DTH S4 x 5 "(127 mm) does not use a foot valve and the cutting structure has spherical buttons in the gauge and ballistic in the front, selected to suit the application. Please see the life of the hammer when compared to competition as below:

Comparison Before & After

Performance of Competitor’s Hammer – Service life (Average) 6,000 meters. According to quarry statistics, its discarding is due to the wear of internal components. CONTROL TUBE (Control tube) and piston failure

Hammer JDC45S

Overall 7000 meters were drilled, with normal wear and with 13% higher ROP than competitor the hammer delivered increased performance and longer life. The hammer was removed because it presents a wear on the chuck side. The hammer can continue working if we change the chuck and Wear sleeve.

Conclusions

1: The testing of the JDC45S hammer and the S4 127mm CONVEX COMBI drill was started on October 1st 2020 and to date an optimum performance was obtained, achieving a good performance.

2: 01 drill bit was used with hammer JDC45S, DISCARDED state, which show Wear of matrix and peripheral and ballistic inserts.

3: This Hammer presents a better performance in meters drilled (m) ROP penetration speed (m/hr) compared to competition.

4: This hammer maintains a good performance maintaining a Good internal air pressure and a Good ROP penetration speed, A CLEAR WINNER OF PERFORMANCE !!!

Quality of Product is the priority & Saideepa will always strive towards continual improvement to generate many such stories.